About Us

In partnership with our clients, our purpose is to unlock the potential of people by delivering sustainable continuous improvement.

We work with businesses of all sizes across a range of sectors. Our unique experience and practical approach to solving business challenges sets us apart.

We utilise a wide range of lean, six sigma, change management, tools and coaching techniques to add value to our clients. Some are well-known approaches such as DMAIC or PDCA, others are bespoke to Calderglen Consulting and have been developed to provide maximum results for our clients.

We take a dual focused approach to attaining sustainable continuous improvement at Calderglen Consulting focusing on sustained results and environmentally sustainable solutions.

Sustained results

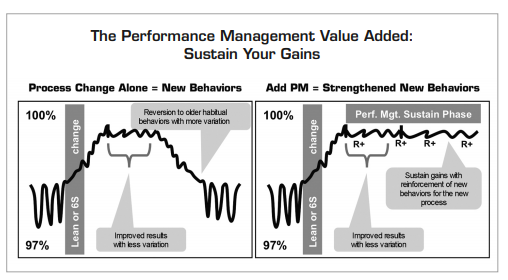

Recent studies say that failure rates for continuous improvement projects range between 50 to 95 percent. While continuous improvement events produce improvement, the results depend on adherence to a new way of doing things, or adopting new behaviours.

We believe that the only way to create a culture of sustainability is to work with your team to design and implement effective change management structures. The science of human behaviour captured in performance management offers techniques for taking new behaviours to high and steady rates making them the new habit. With this consistency of behaviours, improved delivery and lower production costs are then realised consistently.

Environmentally Sustainable Solutions The science is settled. Ninety-seven percent of climate scientists agree that human activity is driving a climate crisis all across the Earth. To hold global warming to 2 degrees Celsius, we need to pursue one simple, powerful goal: reduce global carbon intensity by 7.5% every year.

At Calderglen, we are passionate about doing our part to support our clients build more resilient supply chains less threatened by scarce resources. We believe that lean thinking & eco-efficiency has an important role to play in driving an organisation’s environmental sustainability ambitions. In our experience the paybacks in these areas can come quickly- in months not years.

Eco-efficiency or the science of doing more with less is based on the concept of creating more goods and services while using fewer resources and creating less waste and pollution. Eco-efficiency offers a number of practical benefits, such as:

- Reduced costs through more efficient usages of energy and materials

- Improved environmental performance by reducing toxic emissions and increasing the recovery and reuse of “waste” material

- Reduced risk and liability by “designing out” the need for toxic substances

- Increased productivity and employee morale through closer alignment of company values with the personal values of the employees

Our Implementation Experience

- Consultant implementation lead for European confectionary company across 4 countries:

- Deep dive loss analysis and identification of key improvement projects

- Implementation of quick win program targeting OEE & yield losses delivering high six figure annualized savings.

- Implementation of daily management system.

- Implementation lead for UK soft drinks manufacturer have conducted deep dive loss analysis study that identified over £500k of improvement projects. Now supporting implementation of these initiatives. Significant quick wins realized to date including breakthrough process CIP improvements following European Hygienic Engineering and Design Group best practice guidelines.

- Client-side implementation experience across brewing, distilling and packaging sites internationally, examples include:

- Filler waste levels reduction from 20% to 0.1% across bottling and canning lines.

- OEE improvement projects / methodologies using a range of Lean Six Sigma tools (e.g. SMED, DMAIC) to deliver lines performing at levels of approximately 70% OEE.

- Client-side lead plant process engineer for world scale chemical production plant delivering breakthrough reliability improvements and 10% cost of production saving through focus on reduced variation.

- Utilities reduction program in major grain whisky distillery delivering over £1million in annualized utility reductions and 30% reduction in water consumption.

- Delivering capital projects from £10k to £2M across utility infrastructure, process equipment, packaging machinery and industrial automation.